Wire, pretreatment.

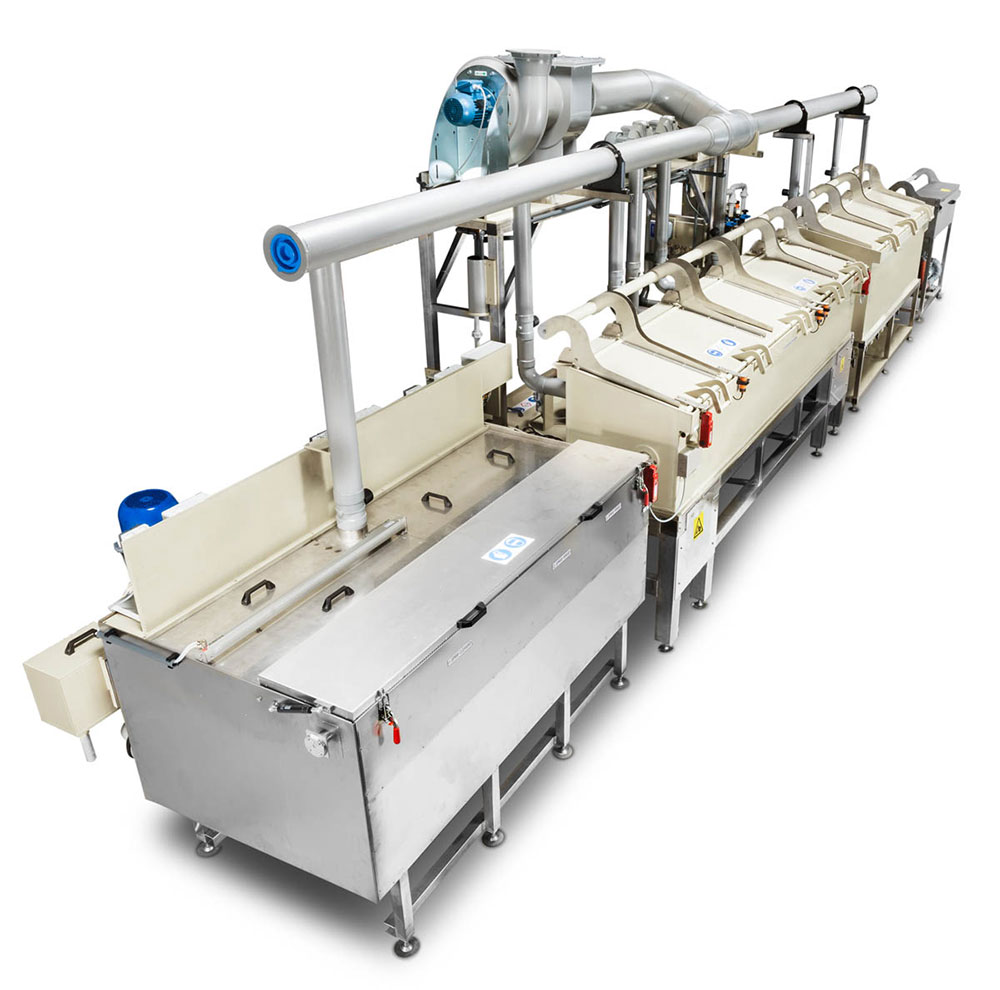

Candor develops and manufactures plants for continuous wire cleaning and pre-treatment. These plants can be divided into the following main categories:

Candojet HW

Highly effective and environmentally-conscious technique for high pressure cleaning of wire with hot water in line with a drawing machine or rolling mill. Read more abour Candojet HW here.

Ultrasonic degreaser

Cleaning of lubricant, oil and emulsions from wire and strip often placed in-line with heating furnaces, hot-dip galvanizing baths or used as a pretreatment prior to other processes. Read more about the ultrasonic degreaser here.

Ultrasonic degreasing High Speed

High Speed – cleaning of lubricant, oil and emulsions from wire and strip with high speed, often placed in-line with heating furnaces, hot-dip galvanizing. Read more about ultrasonic degreasing here.

Electrolytical degreaser

Cleaning of lubricant, oil and emulsions from wire and strip often placed in-line with heating furnaces, hot-dip galvanizing baths or used as a pretreatment prior to other processes. Read more about electrolytical degreaser here.

Cleaning of welding wire

Cleaning of stainless steel alternative copper welding wire in-line with drawing machines with high wire speed.

Chemical and Electrolytical Pickling

Pickling of wire before drawing with different kinds of pickling in order to remove oxides before the next operation.

Want to know more?

Adam Högqvist

Anläggningar, Försäljning- och marknadschef

+46(0)11 - 21 75 31

adam.hogqvist@candorsweden.com

Contacts

Find all contacts here.